Little Beauties

I wanted to find out more about the dried fruit I despise with a passion and some of the other more delicious dried treats Ian Wastney and his family produce under the Little Beauties brand.

Feijoa is one of those flavours you either love or hate, I obviously fall into the second category, I don’t know why but I just don’t like them; no let’s rephrase that, I loathe them. There is no in between with feijoa, it’s one of the few fruits that invokes a love-hate response and is probably the only fruit I don’t eat.

Having got that off my chest I wanted to find out more about Little Beauties and I wanted to taste dried feijoa to see if my attitude to the fruit could be swayed.

Little Beauties is a business that produces dried fruit products and is the brain child of Ian Wastney, his wife Sally and their sons Tristan and Alexander.

The business started in 2012 when he decided to scale-up his production of the fruit many people love and then started experimenting with different ways of using it, drying was an obvious option so Ian and Sally started making small batches in a domestic food dehydrator in their kitchen at home.

Since moving into a factory with seriously upgraded equipment, compared to the home dehydrator, four years ago they have increased production to around 5-6000 packets of feijoa annually and added other fruits to the range they dehydrate and package.

Since moving into a factory with seriously upgraded equipment, compared to the home dehydrator, four years ago they have increased production to around 5-6000 packets of feijoa annually and added other fruits to the range they dehydrate and package.

However dried feijoas are now only a small part of this quickly evolving business, I use the term ‘evolving’ because Ian says they wanted the business to grow organically, they had to prove that there was a market for their dried and chocolate-dipped treats before they invested a huge amount of money and effort into turning a small business into a much bigger enterprise.

Let’s focus for a short time on the fruit I despise, Ian laughed and told me Sally hates the fresh fruit too but eats it in its dried form so there is hope for me.

When I visited the Little Beauties factory last week Ian explained their current processes use machinery to do the peeling, slicing, topping and tailing but the current process isn’t fully automated, “while we use machines there is a lot of manual handling in the middle – sorting, laying the slices into trays for dehydrating and lots of manual lifting and shifting the fresh fruit and waste.

“We quickly realised that relying on feijoa wouldn’t work as a business, the whole season is only about six or seven weeks and we need to process the fruit pretty much right away, it can’t be kept for months like kiwifruit and apples.

To achieve the perfect slice for drying by dehydrating the fruit has to be ripe but not soft, “we need sugar and flavour development without being over-ripe, if the fruit is over-ripe it just gets squashed when we try and process it.”

Making the perfect dried slice of fruit also results in lots of trimmings, “cows love the skins and a cider maker takes the trimmings to make an apple and feijoa cider but we will eventually look at other uses for the waste, right now we are focusing on this part of the business to make sure we get it right rather than trying to grow too quickly.

“Now we know there is a strong market for our products we can focus on growth, we also know what we can automate, what new machinery we need and the amount of raw product we will potentially need to roll out new products in the future.

“Any new products have to be new, not just reinventing something someone else is doing and we want to add value to Nelson produce, having said that we are going to outgrow the production of kiwifruit available to us in the region.

Dried kiwifruit is a significant part of the existing business and for future growth according to Ian, they get their Sungold Kiwifruit from Thomas Brothers in Riwaka and he says because of the outstanding job Zespri are doing in the international market place customers already know what kiwifruit is so it makes it much easier to enter new markets with the Little Beauties dried products.

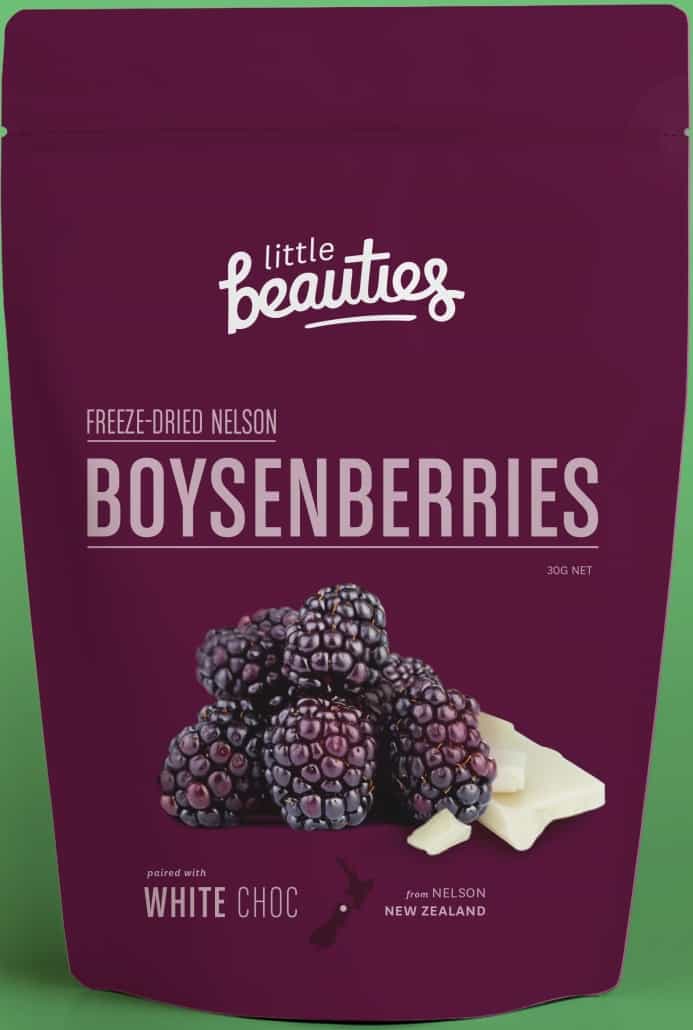

When it comes to the freeze-dried products Ian says the technology to do that is very expensive and also needs a high level of technical knowledge so they contract Absolute Wilderness to do that for them.

“Grant McDonald & his son Andrew own the business and they are really innovative in the stuff they are doing. Grant is a food scientist and his forte is taking new products and scientifically proving and improving them, so we are working with them to freeze-dry the boysenberries we have hand-picked for us at Tasman Bay Berries.

“Grant McDonald & his son Andrew own the business and they are really innovative in the stuff they are doing. Grant is a food scientist and his forte is taking new products and scientifically proving and improving them, so we are working with them to freeze-dry the boysenberries we have hand-picked for us at Tasman Bay Berries.

“In both cases it means we are working with other local specialist businesses, just as we’re doing with the Little Box of Sunshine that’s full of Nelson produced goodies.”

The whole family is involved in this business in one way or another, “our son Alexander and his wife Kristin own a design business in Hamilton and have done all our packaging and branding while our other son Tristan deals with the logistics and planning side, while his wife Sylvia is heavily involved in the factory production and product distribution.”

Bill Findlater took us to Hong Kong to the vegetarian food show and took one of our colleagues to China so he has helped us make some outstanding contacts there, the whole China thing holds a lot of promise but can be quite tricky so having an expert like Bill who has great contacts and understands doing business in China is invaluable to us.”

So what about those dried feijoas, I think it’s fair to say I still hate fresh feijoa and probably wouldn’t choose to eat the dried version but, to my palate, they are nowhere near as offensive as the fresh version.

For me the pick of the bunch is the freeze-dried boysenberries dipped in white chocolate, they are outstandingly tasty.

Published in the Nelson Mail 08.05.19